This 3D-printed shoe company is the future for both sustainability and fashion

Imagine a world where footwear is regenerative… Where the soles of your trainers never wear away, where their comfort and design are still of the highest quality six months after purchase. And then imagine a world where creating shoes isn’t harmful to either the planet or workers, and where producing what we wear on our feet uses less energy than a hairdryer.

That world may sound like something from a sci-fi film, but these ideas aren’t light years away. Zellerfeld, a German start-up with the goal of putting a 3D-printed shoe on every foot in the world, is manifesting a brighter future for fashion.

Working late for yet another night, Zellerfeld’s CEO, Cornelius Schmitt, jumps on a call from Hamburg. There are rows and rows of printing units in the background. What quickly becomes apparent is the level of passion put into the business by Schmitt, who is not only a diehard sneakerhead but someone who truly cares about the planet.

At Zellerfeld the aim is for everything to be cyclical. There are no gaps in the production process. From ideation to the finished product, waste and energy are reduced to a fraction of what it normally takes to make a shoe. But what exactly does Zellerfeld do? Well, in simple terms, you design a shoe and they make it for you in a matter of hours. That’s it. This is the best way, Schmitt believes, to keep the sneaker world ignited with imaginative ideas and the invigoration of aspiring designers.

But it doesn’t stop there. Zellerfeld’s processes eliminate archaic and immoral production practices, including child labour, mass shipping, overproduction and waste. Schmitt’s company is now also trialling a beta program where people can send back their shoes and receive another, brand new pair for free, bringing zero-waste upgrades into the fashion world. Zellerfeld really does make you believe that the future is here.

What was behind the initial need to launch Zellerfeld?

I’ve been putting a third of my life into this. I started as a student and mostly I was frustrated with all of the shoes that you see right now. As an engineer I knew 3D printing and it grew out of the frustration of not seeing cool designs. When you look on Instagram you see so many passionate footwear designers who draw beautiful shoes where you can feel the love in them, and I wanted to have those shoes. I then started to develop all of the printers and the software, and now we print shoes at the push of a button. This way we can help new designers do things that they would otherwise risk their family savings for.

Is that the core reason you wanted to start it, to help aspiring designers?

We believe that experimenting should be very cheap because cool new designs can emerge. With 3D printing the machine doesn’t care if today it’s one design and tomorrow it’s a completely different design, and you don’t have to change anything. What often happens is designers have an idea in the morning, throughout the day they 3D model it, and in the evening they send us the file. Two days later they get their shoe, they put it on Instagram and then they collect orders. We love that because we’re sneakerheads, we just love to see new styles emerge.

There have been flaws within the fashion industry in terms of sustainability since the outset. How does Zellerfeld offer a better, more sustainable alternative?

Firstly you don’t have any of those upfront investments, you don’t have the minimum-order quantities. We don’t care if you order one pair or 10,000 pairs. You don’t have any waste from overproduction. Because those machines are automated, they can be where the consumer is – they can produce decentralised, so you don’t have any shipping, in a sense. You have no waste because everything that is being printed can be used, you don’t have any scrap material. What we love about our shoes is that they’re fully recyclable, we print only using thermoplastics. They get washed and can be made into new printing material again.

Do the low levels of energy used to create 3D-printed shoes outweigh the negatives of traditional practices?

You have all of the shipping components, all of the sourcing of the materials – often a modern sneaker consists of 30 materials that all have to be sourced and shipped separately. The monoliths [Schmitt points behind him at the printers.] have been very energy inefficient, in a sense. Each is one printer that has its own power supply and cooling system, but now we’ve built clusters of ten that print into one big machine, which has only one plug, one cooling system. The entire cluster has ten printers and when it’s running, it consumes less energy than a hairdryer.

On top of that, you’re also removing the child-labour aspect, right?

Here it’s such a nice process that you don’t need to exploit people. So finally products can be made with technology and people overseas are not being exploited.

Zellerfeld functions on a circular production economy – how does the ability to reprint a shoe play as an advantage?

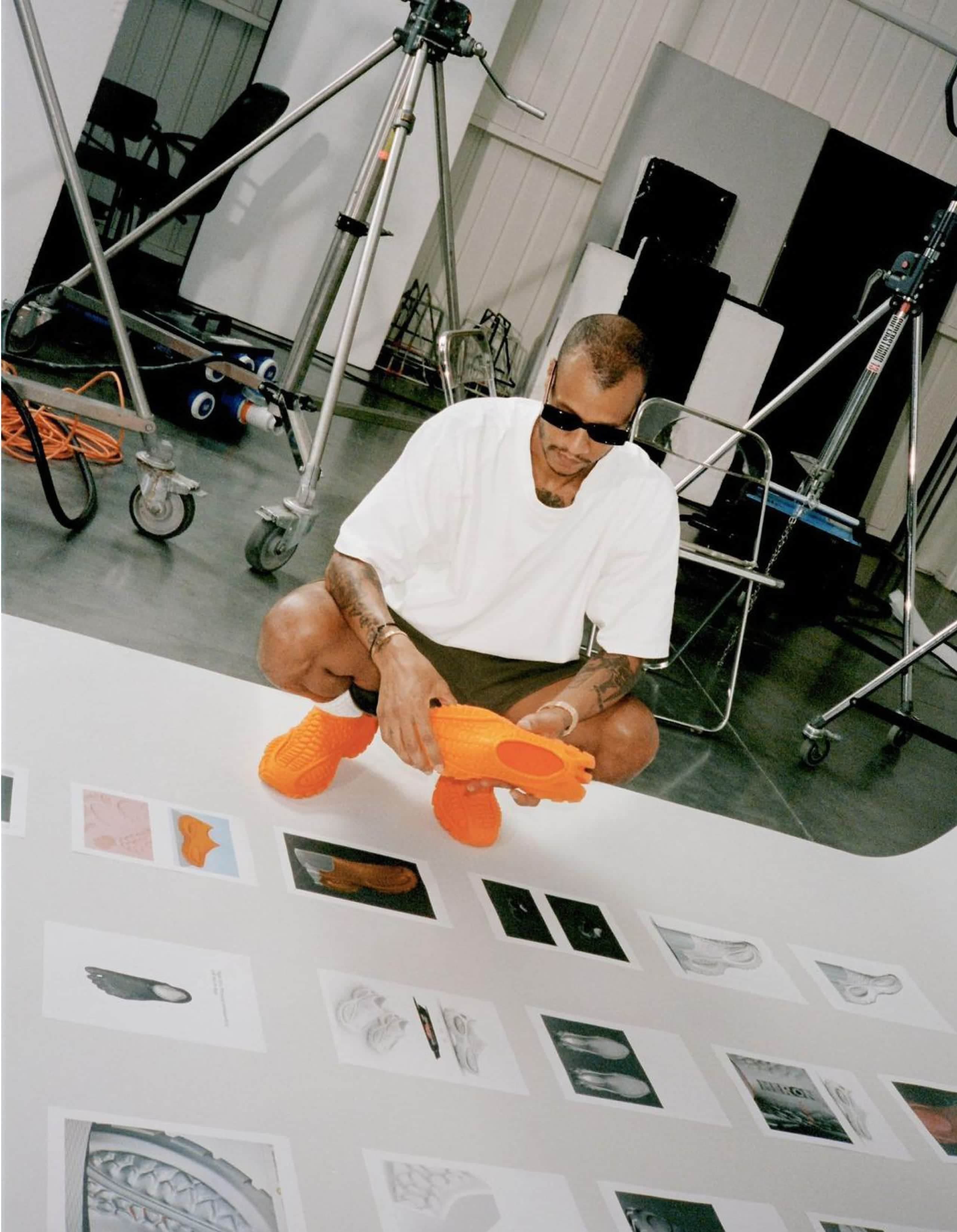

Right now, sourcing printing materials is quite expensive, so being able to reuse materials, especially for 3D printing, obviously helps on the cost side. But what I also love is our beta program where you are expected to send the shoes back. Usually when you buy shoes the relationship between producer and consumer is one-directional. As a producer, you send a shoe and then you never hear back from them again. So we launched the beta program that we did with Heron [Preston, the American designer and artist] and you get a notification to say, “Hey, you can send in your old shoes and we will give you your first update for free. When you send them in we can reuse parts of the material and print you another pair.” The great thing about this is it not only helps with material costs, but it helps us analyse the shoe so we can see where they have been worn, where the weak points are.

What effect do you think this can have on the whole hype-consumer market, which looks for unique, limited-sale items?

I still believe this technology will be great for exclusive shoe drops. So if Maisie [Williams] wants to do a shoe and just share it with her ten best friends, she should be able to do it. If she wants to say that there are only ten pairs and never again will we produce another pair, that’s no problem, because we don’t have any other investments, it’s easy. But we’re not doing this for the hype. We want to place printed shoes onto every foot in the world – that’s why we do it, because we believe it’s the better way for footwear, and better for everybody.

What does the whole process mean in terms of freedom of creativity? How wild can you be?

You can buy yourself an Oculus [VR headset], get Gravity Sketch on it, and it will probably take you a week to learn it. But then you can make your own shoe that you can wear. This is what we see many designers doing. It’s insane how easy it has become, especially with VR. The barriers are super-low. Usually, as a designer, you have to work with a production team that helps you figure out all the sizing, because it needs to be graded differently, you can’t just scale it up in every dimension. But because all of this is a 3D model, it’s easy to compute. We’ve built algorithms that mean designers can give us a shoe in a sample size as a 3D model and we just push a button and then we have all of the sizes. We give all of the tools to the designers because we really want them to make the best shoe design possible, while we take care of the production stuff.

What does this liberation of creativity mean for the future of fashion?

Many sneakerheads, when they get their first Jordans, it’s such an emotional experience as you feel that someone really loved what they did there. You don’t feel it nowadays. Some people might have felt it with some Apple products years ago. I truly believe that with designers being able to be credited for their work, you will feel the love again, they will go the extra mile to do something incredibly great. We can feel this in the shoes that we get as 3D models, and it just feels so different, so refreshing. I really hope that it will bring a smile to people’s faces when they get something that people have put lots of love into. When you get an updated shoe six months after you get your first shoe, the technology will have gotten better again, so the fit might have gotten better. You won’t be buying a product that is just one product any more, but you’ll get updates over time. It’s more like an asset.

Generally speaking, how long does it take to create a product from ideation to completion?

Usually between nine and twelve months in footwear, and here you could have an idea in the morning, throughout the day you 3D model it, and in the evening you print it. The next day you have it on your foot. So it’s one or two days. I’m not sure if you saw the shoes we made for Elon Musk and Grimes’s child… The brand from Paris sent us a sketch, we 3D-modelled it and five days later it was shipped. We did a shoe with KidSuper, a very cool brand from New York, and he asked if we could make a shoe that looks like a slide he handmade in clay. He thought it would take months but he was able to wear it three days later at a Louis Vuitton show in Paris.

Even though 3D printing started up in the Eighties, it’s only properly gaining deserved traction now. What more do you want to do with 3D printing?

What I love about what we’re doing is that we’re lowering the barriers of entry from $500,000 to, like, $10. All of a sudden, everyone can contribute. This way footwear gets better. People can come up with new ideas of how to make soles function better, or how you can make the shoe fit better. And why should that stop with footwear? You could have that for almost everything around you. So many parts can be printed – furniture, home appliances, houses. As soon as you remove the barrier to entry, so much cool shit can emerge that today no marketing department would bet on. But I am sure there are some great ideas dying just because it’s too risky.